THERMOPLASTIC PRODUCT

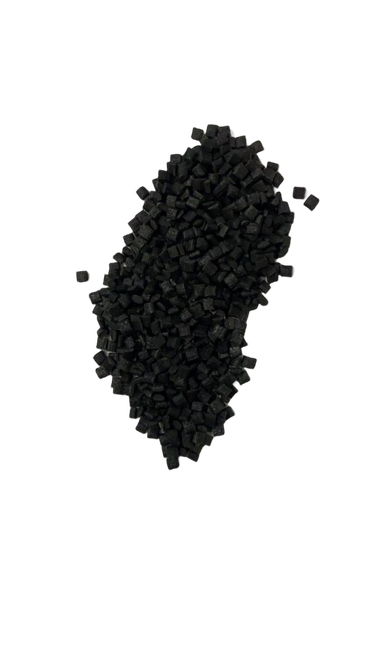

Any plastic substance that melts beyond a particular temperature and solidifies upon cooling is referred to as thermoplastic. Thermoplastics can be repeatedly melted and reshaped. Before the moulding process, they are typically stored as pellets.

These materials see a wide variety of use in manufacturing products from clothing and non-stick cookware to carpets and laboratory equipment.

THERMOPLASTIC INJECTION MOLDING

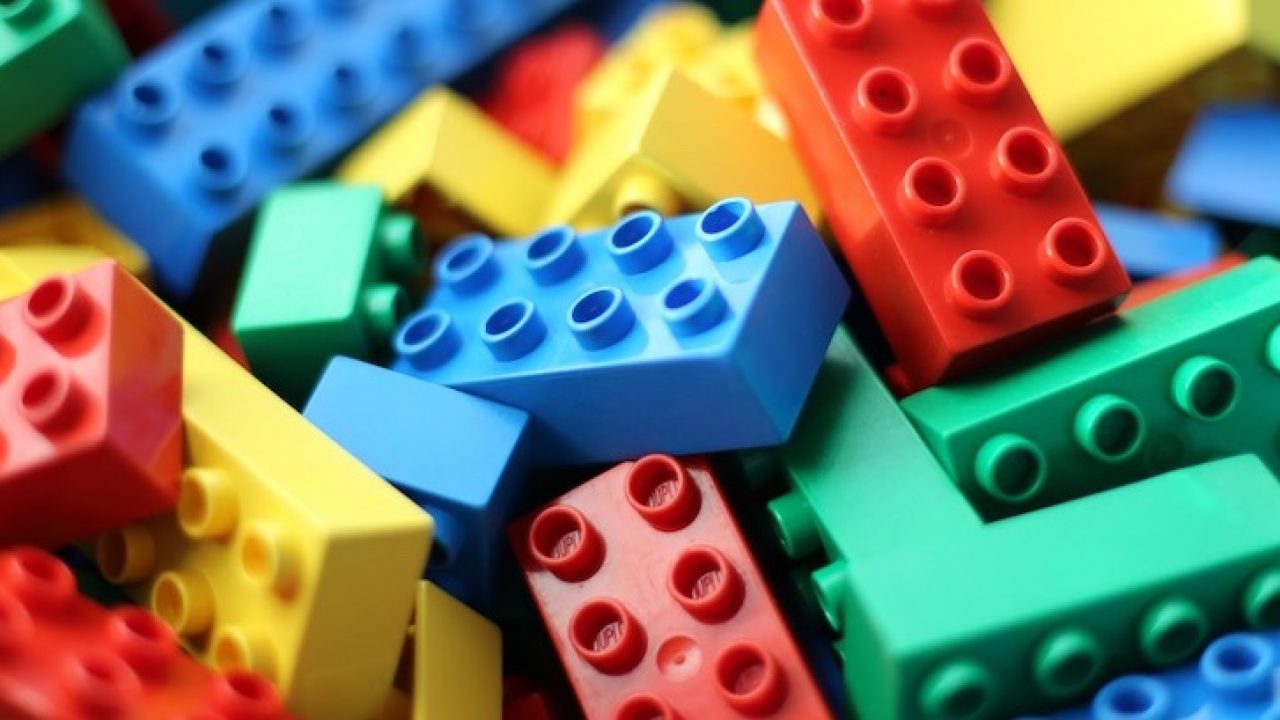

Due to the fact that they generate products that are flexible, accurate, and have aesthetically acceptable surface finishes, thermoplastics are frequently used in the injection moulding process. The ability of objects made from thermoplastics to be remelted and moulded into multiple shapes using the injection moulding technique makes them highly prized for their recyclability. Because it enables parts to be recycled and rebuilt after experiencing damage, wear, and tear, thermoplastics are increasingly popular in the toy, furniture, and garment sectors.

ABS

A typical thermoplastic polymer used for injection moulding applications is ABS. This engineering plastic is well-liked because it is inexpensive to produce and is simple for plastic makers to machine.

PBT

In the electrical and electronic sectors, polybutylene terephthalate is a thermoplastic engineering polymer that serves as an insulator. It is a kind of polyester and a thermoplastic crystalline polymer.

PP

Thermoplastic polymer polypropylene, commonly referred to as polypropene, is employed in a wide range of applications. It is created from the monomer propylene using chain-growth polymerization.

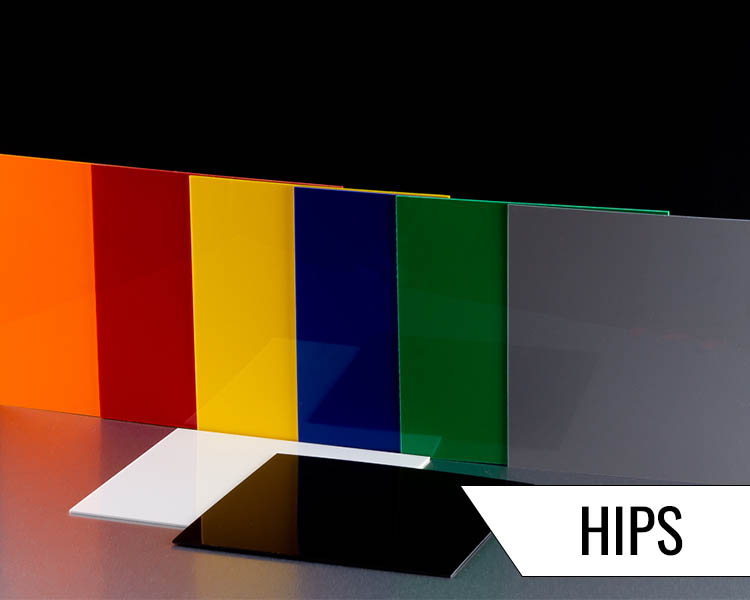

HIPS

HIPS is one of the most functional and cost-effective plastics on the market, and in this blog, we’ll go over its history, production process, and availability.

PBAT

PBAT is made by numerous companies and is sometimes sold under the trade names ecoflex, Wango, Ecoworld, Eastar Bio, and Origo-Bi.

RMP

Paints, plastics, and paper all contain melamine and its salts as fire retardants. Basofil, a melamine fibre with low thermal conductivity.

POM

Engineering thermoplastic poly-oxy methylene also referred to as acetal, polyacetal, and polyformaldehyde.

NYON

Nylon is categorised as a “thermoplastic” material, as opposed to a “thermoset,” because of how it reacts to heat.

PPCP

(PPCP) is a substance that is unscented, colorless, nonflammable, and non-reactive. Look at the product description.

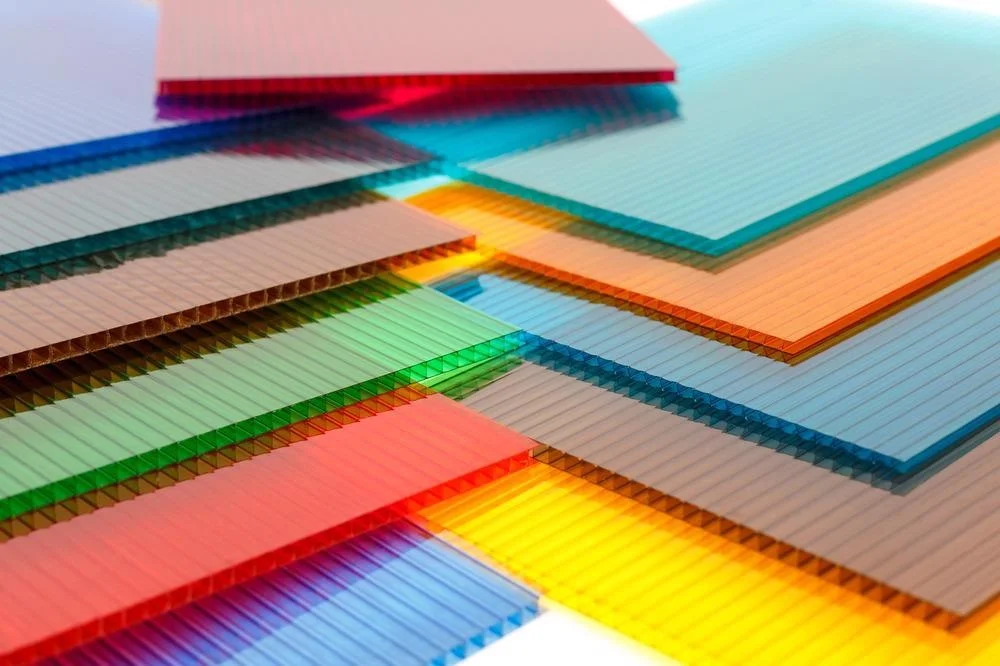

POLYCARBONATE

The material is often utilized to create backlit instrument panels and protective wire and cable casings in airplanes.

PLA

Polylactic acid, usually referred to as PLA, is a thermoplastic monomer made from organic, regenerative resources like sugar cane or maize starch.

NGF

A synthetic polyamide thermoplastic known as “glass-filled nylon,” it is one of the most significant materials used in engineering because of its strength and heat resistance.

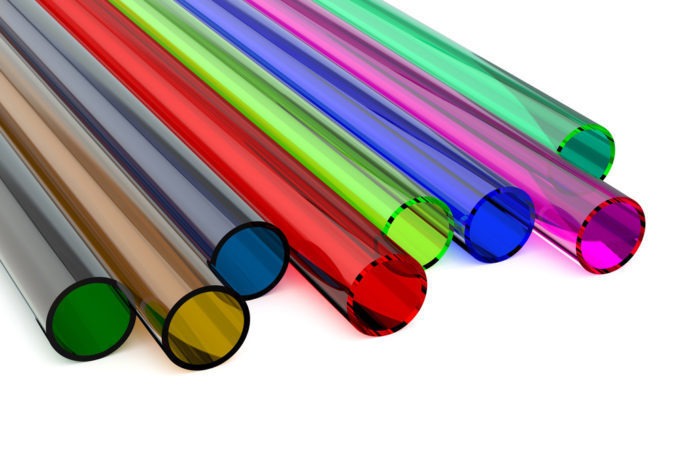

GLASS FIBER

Glass fibre is a substance comprised of several tiny glass fibres. One of the most adaptable industrial materials available today is the product.

SOME INTERESTING

FACTS & FIGURES

The goal of founding Lexus International (India) was to deliver the highest quality while continuously updating skills and technology. Along with providing our customers with standard products, we also make an effort to deepen our expertise in order to produce top-notch solutions.